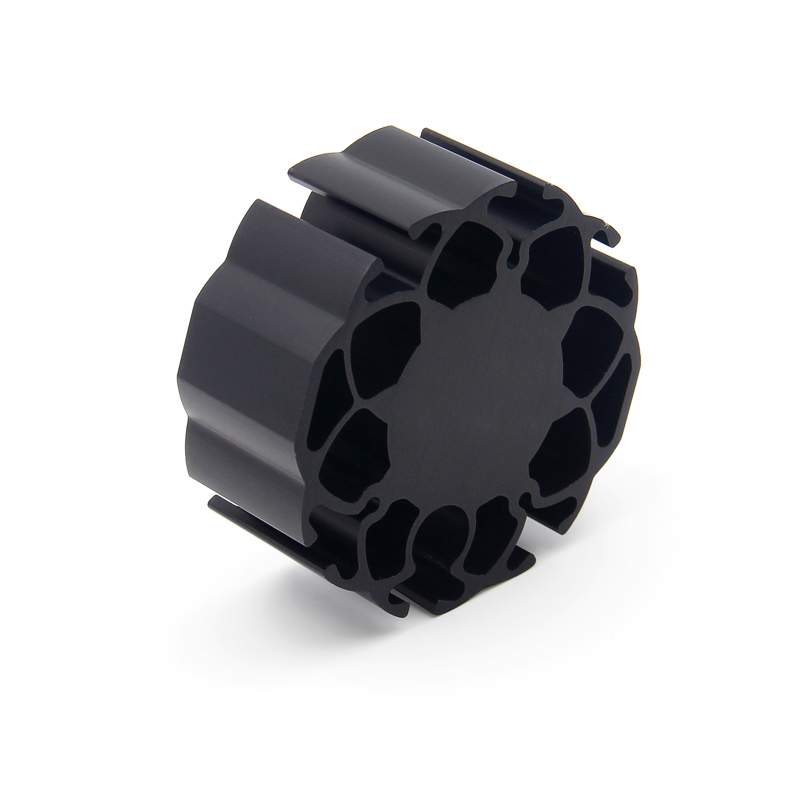

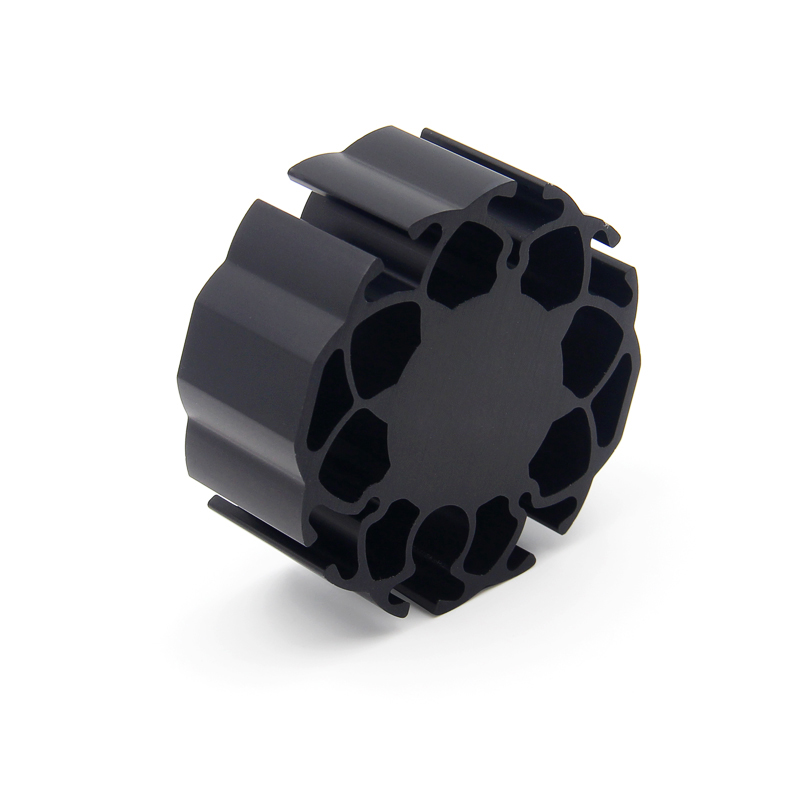

Aluminum Heat Sinks are critical components for thermal management in LED lighting, power electronics, automotive control modules, inverters, and industrial automation systems. At Jiesheng Hardware, we provide CNC-machined, extruded, skived, or forged aluminum heat sinks tailored to your design, ensuring superior heat dissipation performance and long-term reliability.

Whether you need passive fin-type, active heat sinks with fan mounting holes, or custom-shaped cold plates, we deliver precision-machined solutions with fast turnaround and high repeatability.

Aluminum 6061-T6 – Great strength, machinability, and corrosion resistance.

Aluminum 6063-T5 – Ideal for extruded fin-type heat sinks, excellent thermal conductivity.

Aluminum 1050 / 1070 – High thermal conductivity, used for skived or bonded-fin sinks.

Extrusion Machining: Custom fin shapes and profile milling with high-speed CNC routers.

5-Axis CNC Milling: Used for flatness-critical baseplates, complex hole arrays, or mounting brackets.

CNC Turning: For round pin-fin heat sinks or cylindrical LED holders.

Skiving: Fine fins formed from a solid block without bonding.

Surface Treatment: Anodizing (black, clear, silver, blue), chromating, powder coating, nickel plating.

CMM dimensional inspection

Flatness and thermal interface tolerance testing

Surface roughness (Ra < 1.6 µm standard)

Salt spray and corrosion test available upon request

| Item | Specification |

|---|---|

| Material | Aluminum 6061-T6 / 6063-T5 / 1050 / 1070 |

| Thermal Conductivity | Up to 226 W/m·K (Al 1070) |

| Tolerance (Milling) | ±0.01 mm |

| Max Heat Sink Size | 800 mm (L) × 300 mm (W) × 80 mm (H) (customizable) |

| Surface Finish | Anodized (Black, Clear, Custom), Ra < 1.6 µm |

| Mounting Holes Tolerance | ±0.05 mm |

| Fin Pitch | As low as 1 mm (skived) |

| Max Batch Capacity | 1 piece to 100,000+ |

| Prototype Lead Time | 2–3 working days |

| Production Lead Time | 7–12 working days |

20+ Years of CNC Machining Experience

ISO 9001 & IATF 16949 certified, equipped with over 100 CNC machines, including 5-axis, Swiss-type, and automated inspection systems.

Fast Prototyping & Scalable Production

From one-piece CNC prototypes to large-volume extruded/machined assemblies, all managed in-house.

Complete One-Stop Service

Includes design for manufacturability (DFM), CNC, surface finishing, quality control, thermal testing, assembly, and logistics.

Industry Expertise

Serving clients in LED lighting, telecom, electric vehicles, industrial power modules, and consumer electronics worldwide.

Q1: Do you support custom heat sink profiles?

A: Yes. We can machine from customer-supplied drawings or help design based on power dissipation and airflow needs.

Q2: What’s the fastest I can get a prototype?

A: For machined heat sinks, as fast as 2–3 working days. Extrusion die development takes 15–20 days for new profiles.

Q3: Can I get black anodizing or other finishes?

A: Yes. We offer black, clear, silver, red, and custom anodizing, along with powder coating and nickel plating.

Q4: What industries do you serve?

A: LED lighting, automotive electronics, telecom, 5G base stations, industrial inverters, power supply units, and more.

Q5: Do you offer thermal simulation or flatness inspection?

A: Yes, optional thermal simulation can be provided upon request; all machined bases are tested for flatness within 0.05 mm/m.

Q6: Do you offer bonded-fin or skived heat sinks?

A: Yes, for high-power applications requiring maximum surface area density and airflow optimization.

Q7: What file types do you accept?

A: STEP, IGS, STL, DWG, DXF, SolidWorks native files, PDF with key dimensions.