Our Titanium Stem Bolts are manufactured from premium grade 5 titanium alloy (Ti-6Al-4V), recognized worldwide for its outstanding strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. As specialized CNC titanium bolts producers, we focus on delivering precision-engineered high strength titanium fasteners designed for critical applications in aerospace, automotive, Medical, bicycle, and marine industries.

Compared with traditional steel bolts, our grade 5 titanium bolts provide roughly 40% weight reduction, making them ideal as lightweight fasteners for performance-driven projects. The bolts feature CNC-machined threads and smooth finishes, ensuring superior installation experience and reliable mechanical performance.

Material: Manufactured from Grade 5 titanium alloy (Ti-6Al-4V) conforming to ASTM B348, AMS 4928, and ISO 5832-3 standards.

Lightweight & Strong: Our high strength titanium fasteners offer the perfect balance between lightweight design and mechanical strength, outperforming many steel fasteners in demanding environments.

Corrosion Resistance: Exceptional resistance to corrosion, making these Medical grade titanium fasteners suitable for implants and harsh outdoor conditions such as marine environments.

Precision Threads: Produced with advanced CNC titanium bolts machining, delivering accurate and clean threads for smooth and secure fastening.

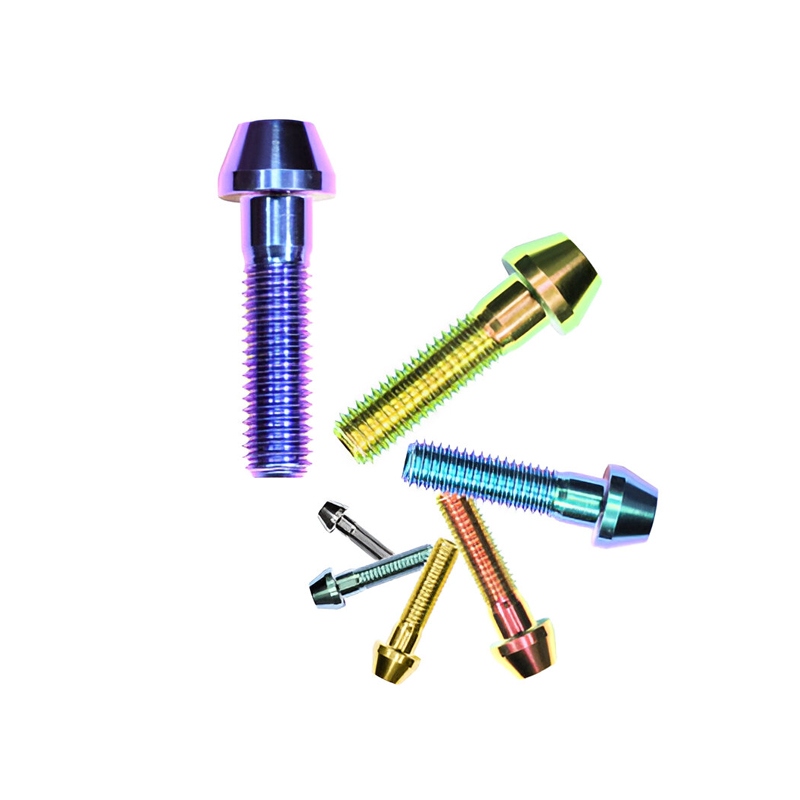

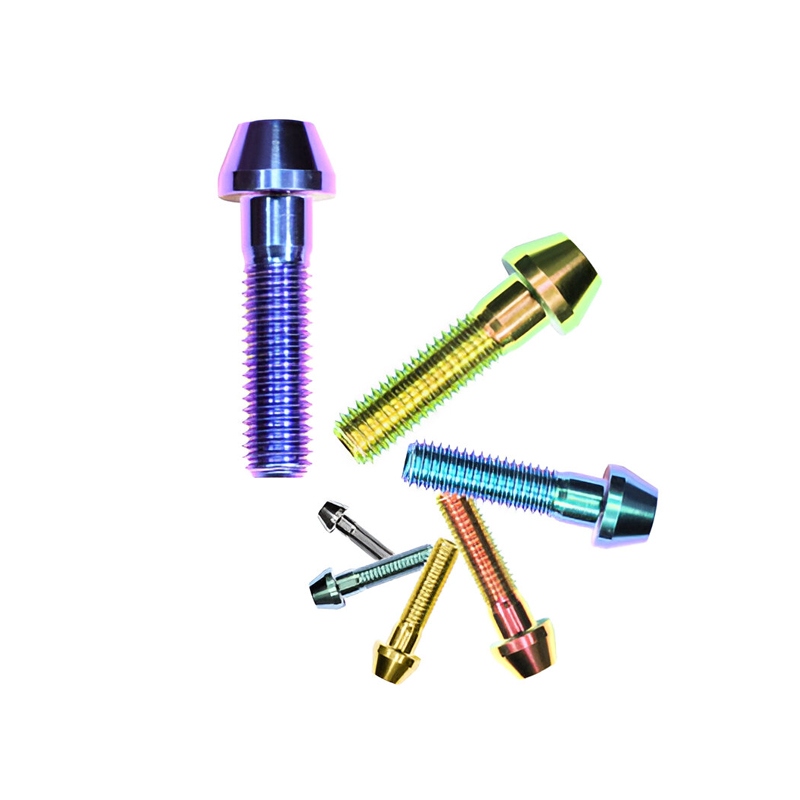

Custom Finishes: Available with natural finish or anodized colors including black, blue, gold, and red to enhance durability and aesthetics.

Temperature Resistance: Maintains mechanical integrity under temperatures up to 400°C (752°F), making them ideal for aerospace titanium bolts and high-performance applications.

Biocompatible: Suitable for medical devices and implants as medical grade titanium fasteners complying with relevant standards.

| Material Type | Grade | Standards |

|---|---|---|

| Titanium Alloy | Grade 5 (Ti-6Al-4V) | ASTM B348, AMS 4928, ISO 5832-3 |

Our titanium stem bolts come with full material certification and traceability to ensure compliance and quality assurance.

Aerospace Industry: Used as critical aerospace titanium bolts in aircraft assemblies requiring lightweight, strong fasteners.

Automotive Sector: Employed as custom titanium bolts in racing and performance vehicles where weight reduction and strength are vital.

Bicycle Components: Widely adopted in high-end bicycles for titanium stem bolts, combining lightness and reliability.

Medical Devices: Used as medical grade titanium fasteners for implants and surgical equipment due to biocompatibility and corrosion resistance.

Marine and Outdoor Equipment: Ideal for harsh environmental conditions requiring high strength titanium fasteners resistant to saltwater corrosion.

Sports and Recreation: Lightweight bolts used in outdoor gear and sports equipment.

Our production utilizes state-of-the-art CNC turning, milling, and thread rolling technology to create precise CNC titanium bolts with tight tolerances. Key steps include:

CNC Machining: Ensures exact dimensions and smooth surface finish on bolts and threads.

Thread Rolling: Improves fatigue resistance and thread strength, critical for performance fasteners.

Anodizing: Optional anodized coating in various colors enhances surface hardness and corrosion resistance.

Heat Treatment: Applied as needed to achieve required mechanical properties and durability.

Quality Inspection: Each batch undergoes stringent dimensional checks, thread profile verification, and mechanical testing.

Dimensional Tolerance: ±0.01mm for critical features to guarantee interchangeability and secure fit.

Material Traceability: Complete certificates of compliance, including chemical composition and mechanical properties.

Mechanical Testing: Tensile strength, hardness, and fatigue tests ensure performance under stress.

Surface Quality: Inspection for smoothness, absence of defects, and consistent anodizing finish.

Compliance: All products meet industry standards for aerospace, medical, and automotive applications.

Thread Types: Metric sizes (M3 to M30) and imperial sizes (1/8” to 1”) available.

Bolt Lengths: Tailored per customer requirements for specific applications.

Surface Treatments: Natural finish, anodizing in black, blue, gold, red, or other custom coatings like PTFE.

Packaging: OEM packaging solutions including bulk, blister packs, or custom labeled boxes.

Design Assistance: Technical support available for custom bolt designs and engineering advice.

Q1: What advantages do your titanium stem bolts have over traditional steel bolts?

Our grade 5 titanium bolts offer superior strength-to-weight ratio, corrosion resistance, and biocompatibility, making them ideal lightweight fasteners for aerospace, medical, and high-performance automotive applications.

Q2: Can you produce custom sizes and thread types?

Yes, we manufacture fully custom titanium bolts with various thread pitches, diameters, and lengths to meet your exact specifications.

Q3: What surface finishes are available?

We provide natural finish and anodized coatings in multiple colors, including black, blue, gold, and red, tailored to your needs.

Q4: Are these bolts suitable for medical implant applications?

Yes, our medical grade titanium fasteners comply with relevant ASTM and ISO standards and are biocompatible.

Q5: What is the typical lead time for orders?

Lead time ranges from 15 to 25 working days depending on order quantity and customization level.

For high-performance, lightweight, and corrosion-resistant titanium stem bolts, contact our sales team today. We provide competitive pricing, rapid prototyping, and expert technical support to fulfill your custom titanium bolts needs.