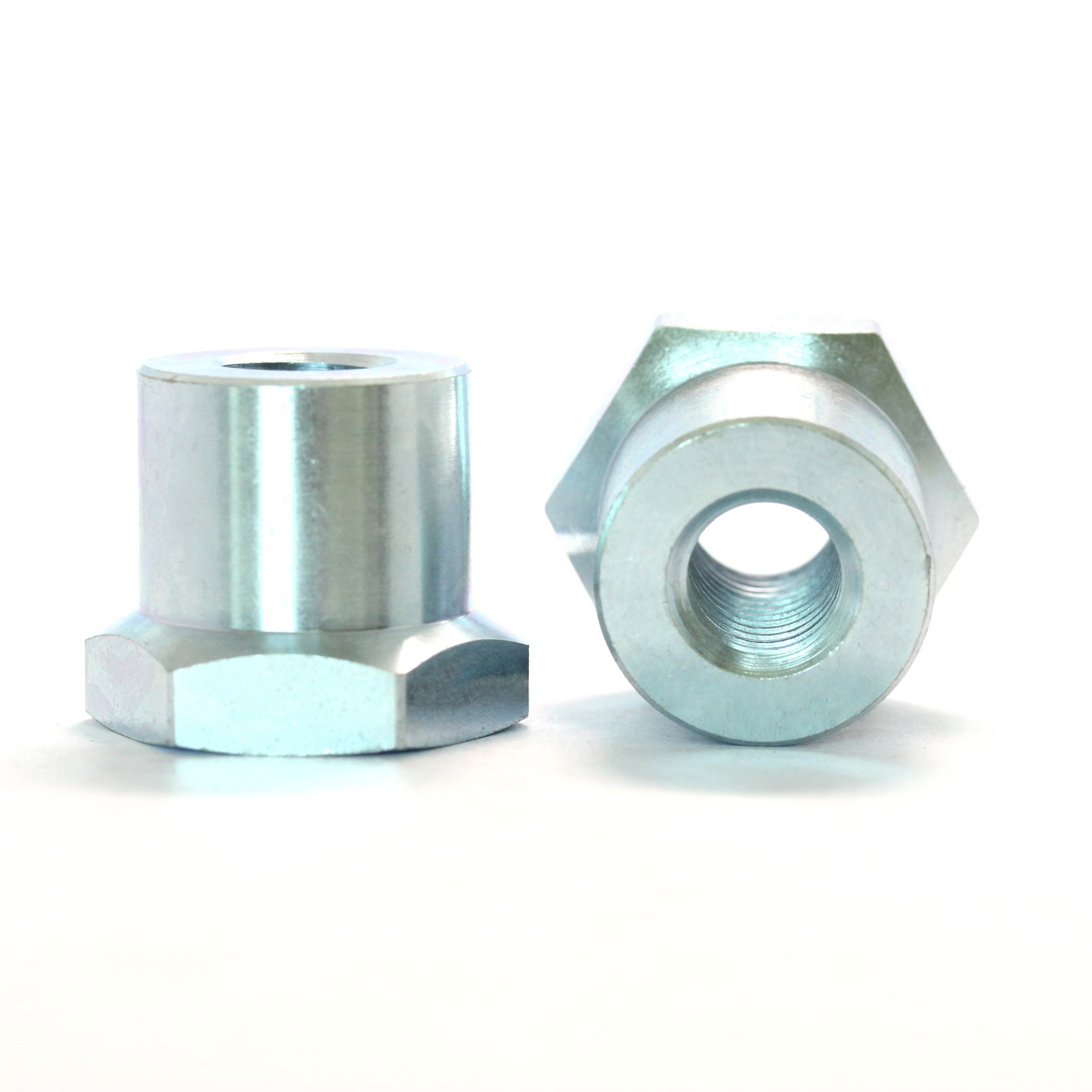

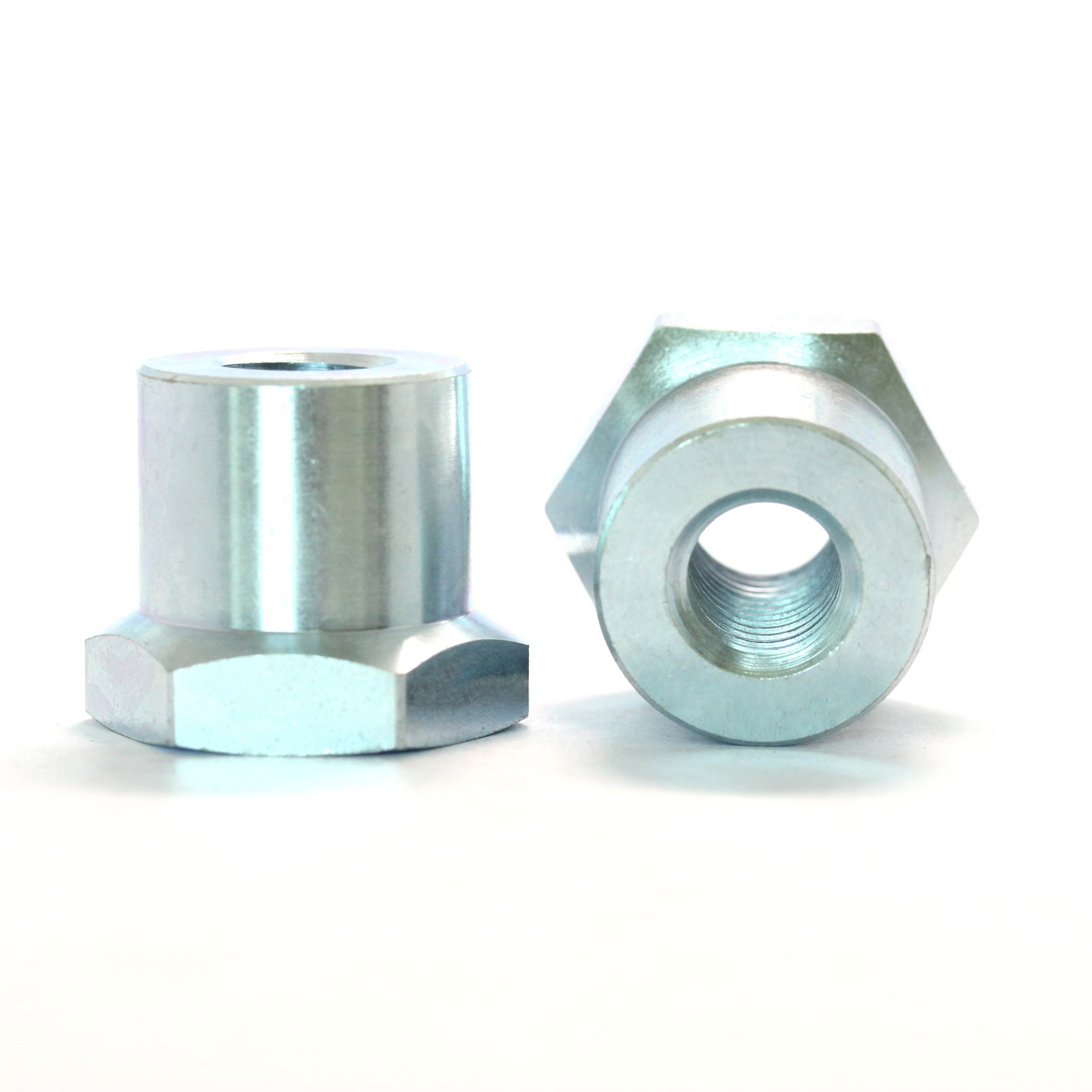

Our Custom Hex Nuts are engineered for high-strength fastening across demanding industrial applications. As a leading custom hex nut manufacturer and hex nut supplier in China, we specialize in producing CNC machined hex nuts, precision hex nuts, and OEM hex nuts tailored to customer drawings, specifications, and performance requirements.

Whether you need custom made hex nuts for Automotive assemblies, aerospace components, industrial machinery, or heavy equipment, we provide reliable fastening solutions with superior precision, stability, and durability.

Metric/Imperial sizes

Fine / coarse / custom thread pitch

Special geometries & non-standard designs

Strength grades customized per application

Using advanced CNC turning, CNC milling, and multi-axis machining centers, our custom hex nuts machining services achieve:

±0.01 mm tolerances

Excellent thread accuracy

Smooth surface finishes

Available in steel, stainless steel, brass, aluminum, titanium, and high-strength alloys for various industry requirements.

High torque resistance

Strong tensile strength

Corrosion-resistant options

Stable in extreme temperatures

As a hex nut factory in China, we support:

OEM hex nuts

Wholesale supply

Long-term production partnerships

Industrial project sourcing

Our custom hex nut manufacturer China production workflow includes:

Material bars, rods, or forgings are selected based on mechanical requirements.

Forged hex nuts for heavy-duty applications

CNC machined hex nuts for ultra-precise components

CNC turning hex nuts for round-to-hex forming

CNC milling hex nuts for custom shapes and slots

High-speed thread rolling, tapping, or CNC threading ensures accuracy and durability.

For applications requiring strength improvement:

Quenching

Tempering

Carburizing

Nitriding

Depending on corrosion resistance and appearance needs:

Anodized hex nuts

Plated hex nuts

Zinc-coated hex nuts

Nickel / chrome plating

Polishing / sandblasting

Fully documented inspections with:

Thread gauges

Vernier & micrometers

CMM measurement

Hardness testing

Salt spray corrosion testing

We offer a full range of materials to meet different industry standards:

SS304 / SS316 / SS316L / SS410

Excellent anti-corrosion performance

Ideal for marine and outdoor applications

Strong, economical, suitable for machinery and structural applications

High tensile strength for aerospace & high-load environments

Lightweight, corrosion-resistant

Ideal for electronic housings & automotive parts

Excellent machinability

Suitable for precision instruments and decorative fasteners

Ultra-high strength-to-weight ratio

Aerospace-grade performance

Our custom hex nuts are widely used in:

Engine systems

Transmission assemblies

Timing mechanisms

High-torque connection points

(Keyword: hex nuts for automotive)

CNC machines

Pumps, compressors

Conveyor systems

(Keyword: hex nuts for machinery)

Robotics

Power equipment

Construction machinery

(Keyword: hex nuts for industrial equipment)

Aircraft components

High-strength fasteners

Lightweight custom structures

(Keyword: custom hex nuts for aerospace)

Corrosion-resistant stainless steel and coated hex nuts provide long service life in harsh environments.

15+ years manufacturing experience

Advanced CNC machining capabilities

Competitive pricing from a hex nut factory China

Strict quality assurance system

Low MOQ for prototypes

Fast lead time for mass production

Full export documentation support

We are committed to being the best supplier for custom hex nuts for global buyers seeking reliable, high-precision, and customizable fastening solutions.

Yes. We provide OEM hex nuts, including full customization of size, thread, material, tolerance, and surface treatment.

Low MOQ is available for prototypes. Mass production MOQ depends on material and complexity.

Absolutely. We specialize in custom made hex nuts and precision hex nuts based on drawings or samples.

Samples: 5–12 days

Bulk orders: 15–30 days, depending on quantity and complexity

We use CMM, thread gauges, hardness testers, and visual inspections to ensure dimensional accuracy and performance.

Yes, including anodized, plated, zinc-coated, polished, and custom surface finishing options.