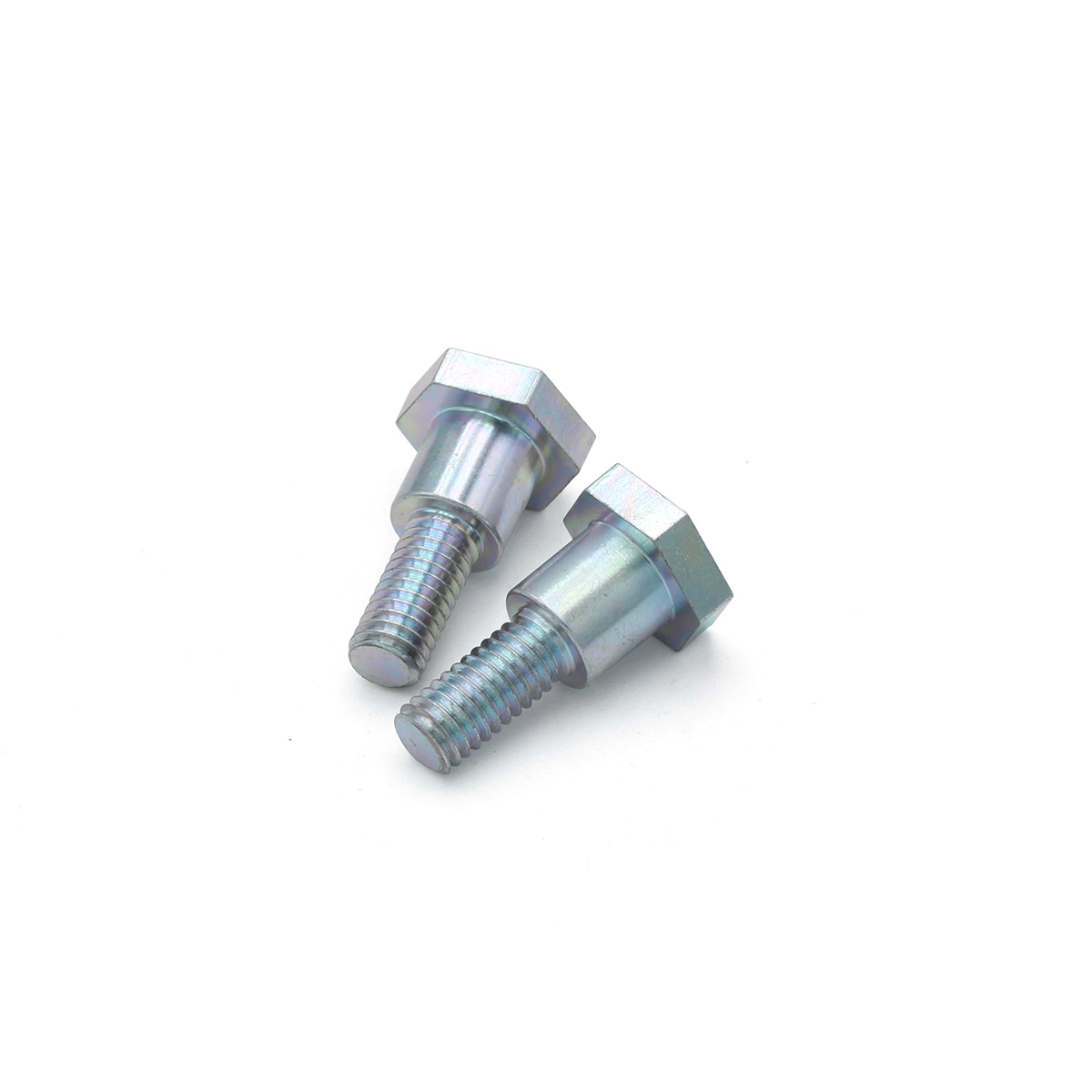

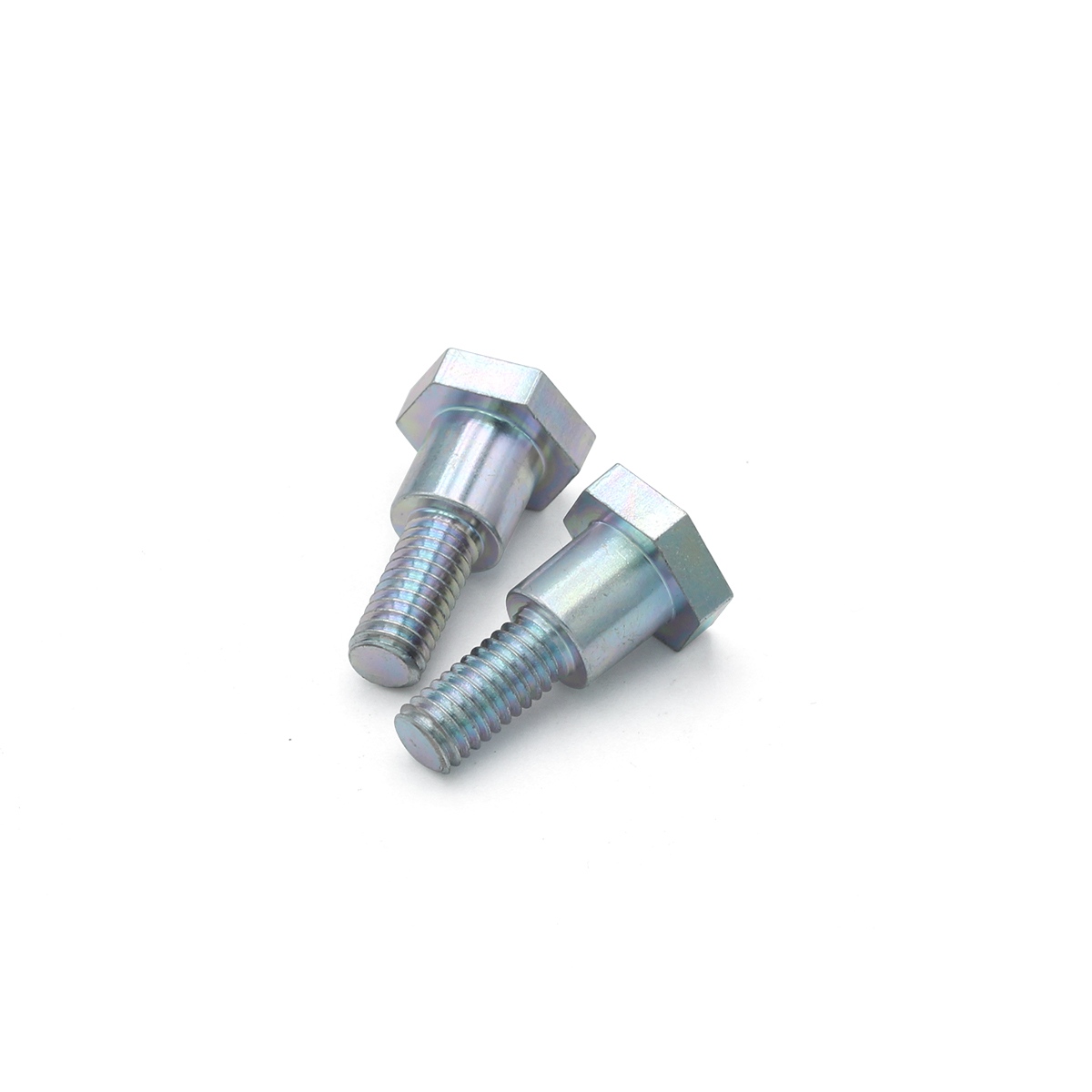

As a leading shoulder screw manufacturer and supplier in China, we specialize in producing custom shoulder screws, precision shoulder screws, and custom shoulder bolts tailored to your specific requirements. Our screws are manufactured with high precision, ensuring excellent concentricity and tight tolerances for mechanical alignment and component positioning. With advanced CNC Machining, turning, and milling capabilities, we provide OEM shoulder screws in various Materials, sizes, and finishes — designed for demanding industrial and mechanical applications.

Whether you need stainless steel shoulder screws, alloy steel shoulder screws, or custom made shoulder screws, we can deliver the ideal solution with consistent quality and fast turnaround.

High Precision Machining: Ensures tight tolerance, perfect fit, and consistent performance.

Multiple Material Options: Stainless steel, alloy steel, brass, aluminum, and titanium available.

Strong Customization Capability: Tailored dimensions, shoulders, threads, and surface finishes.

Superior Strength and Durability: Designed for heavy-duty and high-stress applications.

OEM & ODM Services: Flexible customization to meet diverse industrial requirements.

Factory Direct Supply: Competitive pricing with guaranteed quality and on-time delivery.

Our custom shoulder screws are produced using a combination of advanced manufacturing technologies:

CNC Machining: For precise shaping and accurate shoulder dimensions.

Turning & Milling: To achieve high surface smoothness and concentric accuracy.

Thread Rolling & Cutting: Ensures consistent thread quality.

Heat Treatment: Enhances hardness, wear resistance, and mechanical strength.

Quality Finishing: Polishing, electroplating, and anodizing for corrosion protection and aesthetics.

We offer a wide range of materials to meet different mechanical and environmental requirements:

Stainless Steel Shoulder Screws: Excellent corrosion resistance, ideal for marine and outdoor use.

Alloy Steel Shoulder Screws: High tensile strength and fatigue resistance, suitable for heavy-load applications.

Carbon Steel: Cost-effective with high mechanical strength.

Aluminum: Lightweight, corrosion-resistant, suitable for electronics and aerospace.

Brass & Titanium: Non-magnetic, corrosion-resistant, and aesthetically pleasing options.

Our custom shoulder fasteners can be finished with various surface treatments to improve durability and appearance:

Polishing

Zinc Plating

Nickel Plating

Black Oxide Coating

Anodizing (for aluminum)

Passivation (for stainless steel)

As a professional shoulder screw factory, we implement strict quality control at every production stage.

Tolerance: Up to ±0.01mm depending on customer requirements.

Surface Roughness: As low as Ra 0.8μm for smooth finish.

Inspection Tools: Coordinate Measuring Machines (CMM), hardness testers, surface roughness testers, and optical comparators.

Every batch of precision shoulder bolts is inspected to ensure consistent dimensions, thread accuracy, and material integrity.

Our custom shoulder screws and precision shoulder bolts are widely used in:

Automotive Components

Industrial Machinery and Equipment

Aerospace and Aviation

Robotics and Automation

Marine Equipment

Electronic Devices and Instruments

Q1: Do you provide OEM shoulder screws?

Yes, we are an OEM shoulder screw manufacturer offering custom designs based on drawings or samples.

Q2: What is your typical lead time?

Usually 7–15 working days depending on the order quantity and complexity.

Q3: Can you produce non-standard or custom made shoulder screws?

Absolutely. We specialize in custom made shoulder screws and precision shoulder fasteners with tailored sizes, materials, and finishes.

Q4: How do you ensure product quality?

All products undergo strict dimensional checks, surface inspections, and mechanical testing before shipment.

Q5: Can I order small batches for prototyping?

Yes, we support low-volume production for prototype and pilot runs before mass manufacturing.