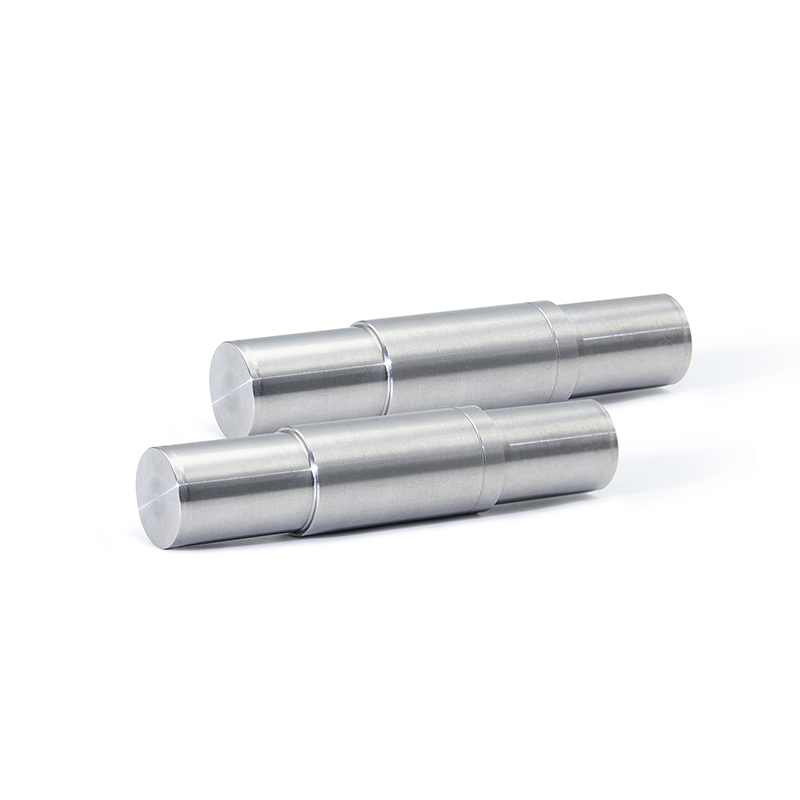

Our CNC Turning Shaft products are precision-engineered components designed to meet exacting performance standards across multiple industries. Manufactured with advanced CNC machining turning shaft technology, these shafts deliver exceptional accuracy, durability, and reliability. As a trusted CNC Turning shaft manufacturer, we offer custom CNC turning shafts tailored to the specifications of automotive, aerospace, industrial machinery, and robotics applications.

High Precision: Achieve tight tolerances and smooth surface finishes with precision CNC turning shafts.

Customizable: Flexible options for diameter, length, Material, and surface treatment to meet unique application needs.

Material Versatility: Available in custom steel shafts, stainless steel shafts, aluminum shafts, and brass variants.

Durability & Strength: CNC machined metal turning shafts are heat-treated or hardened to withstand high loads and wear.

OEM Services: Support for custom CNC turning shaft fabrication services and large-volume production.

We employ advanced machining processes to ensure top-quality shafts:

CNC Turning & Milling: Achieve high precision and consistent shaft geometry.

Grinding & Polishing: Ensure smooth surfaces and optimal fit for rotating equipment.

Heat Treatment: Improve hardness, wear resistance, and fatigue strength.

Surface Coating: Options include electroplating, anodizing, black oxide, and polishing to enhance performance and corrosion resistance.

Custom Fabrication: Tailored CNC lathe shaft production for specialized applications.

Our CNC turning shafts can be manufactured from a variety of materials depending on application requirements:

Carbon Steel: Cost-effective, durable, ideal for industrial machinery.

Stainless Steel Shafts: Corrosion-resistant for marine, food processing, and medical equipment.

Aluminum Shafts: Lightweight, suitable for aerospace, robotics, and automation.

Brass Shafts: Excellent low-friction properties, ideal for precision instruments and bearings.

CNC Turning Shafts are widely used in:

Automotive Industry: Drive shafts, transmission shafts, steering components.

Industrial Machinery: Conveyor rollers, pump shafts, gear systems.

Aerospace & Robotics: Lightweight, precision shafts for control mechanisms and actuators.

Marine Equipment: Corrosion-resistant shafts for motors and propeller systems.

Medical Equipment: Small-diameter precision shafts for surgical and diagnostic devices.

Precision Fit: Reduces vibration and ensures smooth rotation.

Durability: Heat-treated and surface-finished for long service life.

Customizable: Dimensions, materials, and surface finishes tailored to your needs.

OEM Ready: Large-scale production with consistent quality and reliability.

Q1: Can you provide custom CNC turning shafts for specific applications?

A: Yes, as a CNC turning shaft manufacturer, we provide fully custom CNC turning shaft machining services for automotive, industrial, aerospace, and other applications.

Q2: What materials are available?

A: We offer custom steel shafts, stainless steel shafts, aluminum shafts, and brass shafts to suit various performance requirements.

Q3: What is the typical lead time?

A: Lead time generally ranges from 15–30 days depending on shaft complexity and order volume.

Q4: How do you ensure precision?

A: All shafts are manufactured using advanced CNC machines, with inspections using CMM, hardness testers, and surface roughness measurement tools.

Q5: Do you offer OEM services for bulk orders?

A: Yes, we provide OEM services and custom CNC turning shaft fabrication services for large-volume industrial and automotive projects.