What Are Aluminum Machined Parts?

What Are Aluminum Machined Parts?

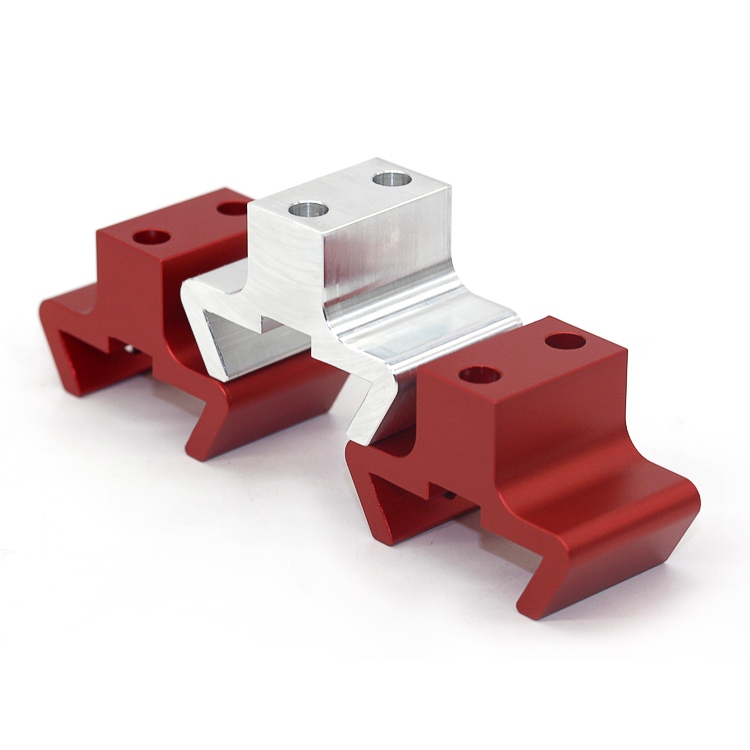

Aluminum machined parts are precision components manufactured through subtractive machining processes such as CNC Milling, turning, or drilling. These parts are crafted from high-grade aluminum alloys (e.g., 6061-T6, 7075-T6, or 2024-T3) to achieve tight tolerances (typically ±0.005" or better) and surface finishes as fine as 32 µin Ra. Key characteristics include:

Lightweight: Density of 2.7 g/cm³ (approximately 1/3 of steel)

High Strength-to-Weight Ratio: 6061-T6 yields 40,000 psi tensile strength

Corrosion Resistance: Natural oxide layer provides 0.002-0.003" passive protection

Thermal Conductivity: 167 W/m·K (4x better than steel)

Electrical Conductivity: 35-40% IACS (International Annealed Copper Standard)

Machinability: 80% rating on the machinability index (vs. 100% for free-cutting brass)

Applications of Aluminum Machined Parts

These components serve critical functions across Industries due to their unique properties:

Aerospace

Structural airframe components (e.g., wing ribs, bulkheads) made from 7075-T6 aluminum withstand fatigue loads up to 75,000 cycles at 30 ksi stress. Fuel system parts maintain leak-proof performance at -65°F to 250°F operational ranges.

Automotive

Engine blocks and transmission housings utilize A380 die-cast aluminum (3.0-4.0% Cu content) for heat dissipation up to 400°F. Suspension components achieve 50% weight reduction versus steel while maintaining 25 kN load capacity.

Electronics

Heat sinks with fin densities of 15-20 fins/inch provide thermal resistance values below 0.5°C/W. RF shielding enclosures maintain 60-80 dB attenuation from 1 MHz to 10 GHz frequencies.

Medical

Surgical instrument components meet ISO 13485 standards with biocompatible anodized coatings (Type II, 0.0005-0.001" thickness). Imaging equipment frames demonstrate<0.1% dimensional="" variation="" across="" 68-86="">

Industrial

Pneumatic system manifolds handle 150 psi working pressures with<0.001" flatness="" tolerances.="" robotic="" arm="" linkages="" maintain="" positional="" accuracy="" within="">

Maintenance Best Practices

Proper care extends service life and maintains performance:

Cleaning Procedures

Use pH-neutral cleaners (6.5-7.5 range) to prevent oxide layer damage

Ultrasonic clean at 40-60 kHz for 5-10 minutes to remove particulate<25µm<>

Isopropyl alcohol (70-99% concentration) for degreasing without residue

Corrosion Prevention

Apply MIL-DTL-5541 Type II chromate conversion coating for salt spray resistance >500 hours

Anodize to 0.002" thickness (MIL-A-8625 Type III) for maximum wear resistance

Store at<60% relative="" humidity="" with="" vci="">

Lubrication

Moving parts: Use PTFE-based lubricants with viscosity 50-100 cSt at 40°C

Threaded components: Apply molybdenum disulfide grease (2-5% concentration)

High-temp applications: Choose silicone-based lubricants stable to 400°F

Inspection Protocols

Measure critical dimensions quarterly with CMM (Coordinate Measuring Machine) accuracy of ±0.0002"

Conduct dye penetrant testing annually to detect cracks >0.001" in width

Monitor surface roughness with profilometers (16 µin Ra maximum deviation)

Storage Conditions

Maintain ambient temperature of 59-77°F (15-25°C)

Separate dissimilar metals by minimum 12" to prevent galvanic corrosion

Use closed-cell foam padding with 30-50 psi compression resistance

English

English